Home Now

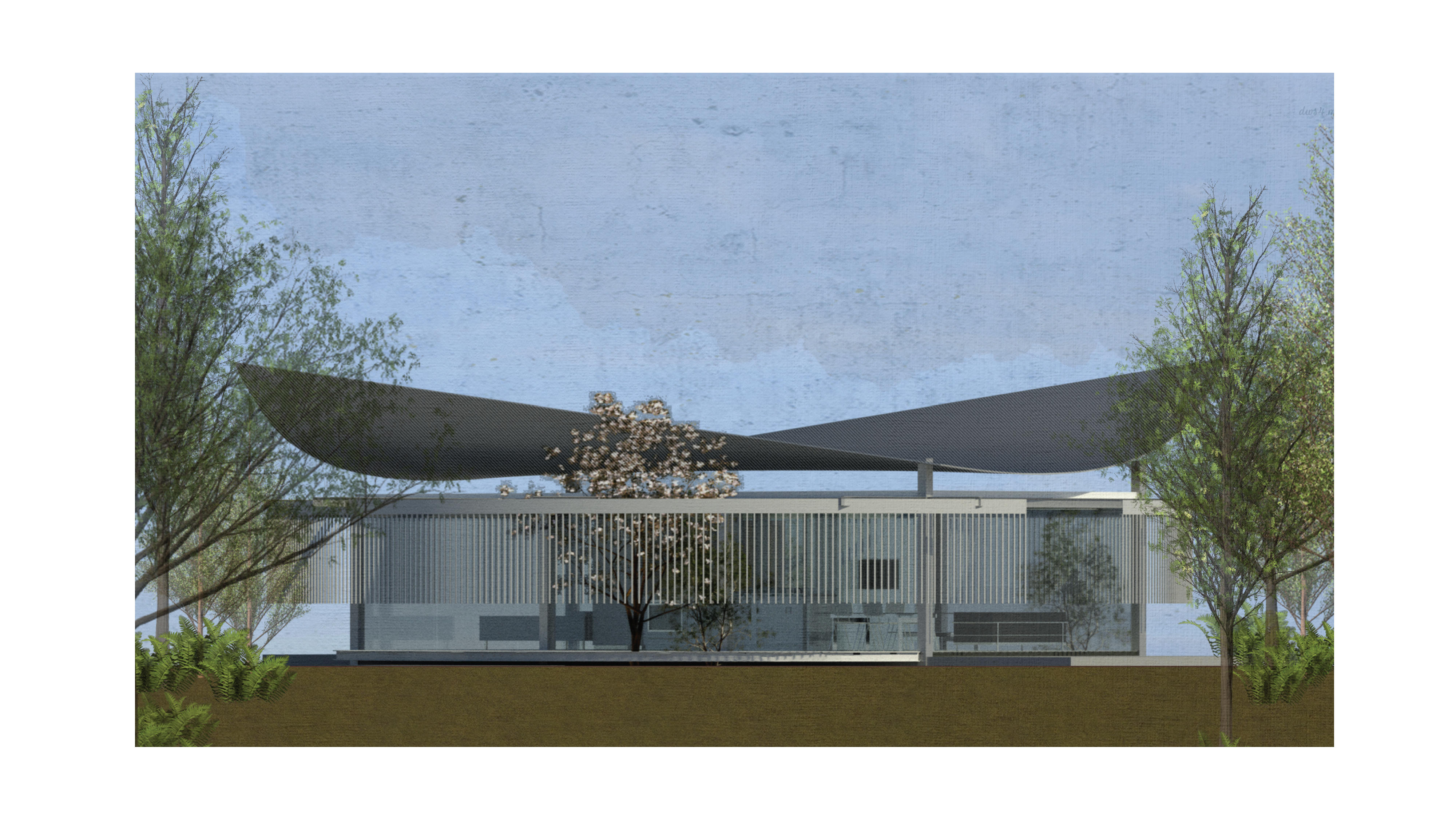

How to treat different layers of a building rather than compress them all into a single wall?

?

A building is most effectively approached through a hierarchy, addressing each layer one after another instead of merging them into a single element.

● Massing

● Interior

● Articulation

● Ground![]()

A building is most effectively approached through a hierarchy, addressing each layer one after another instead of merging them into a single element.

● Massing

● Interior

● Articulation

● Ground

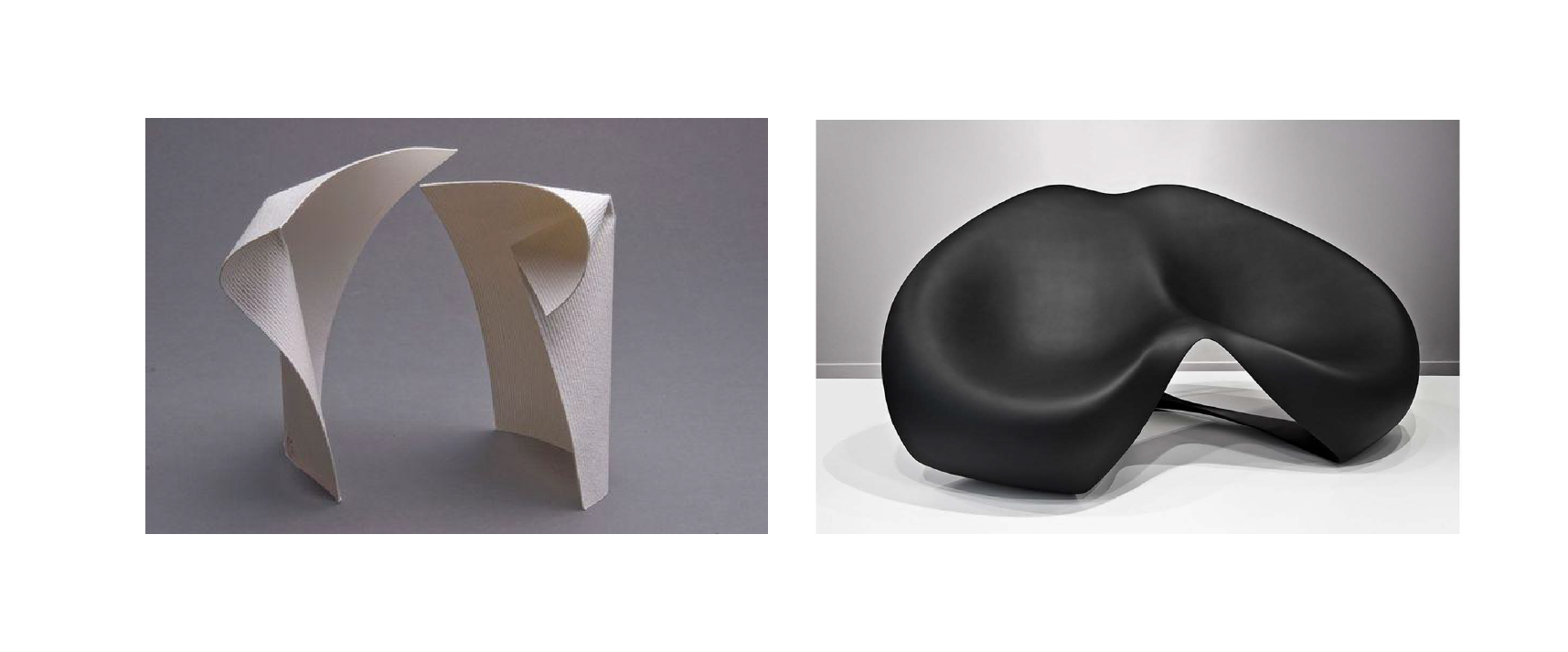

“Designing the material rather than designing the assembly”

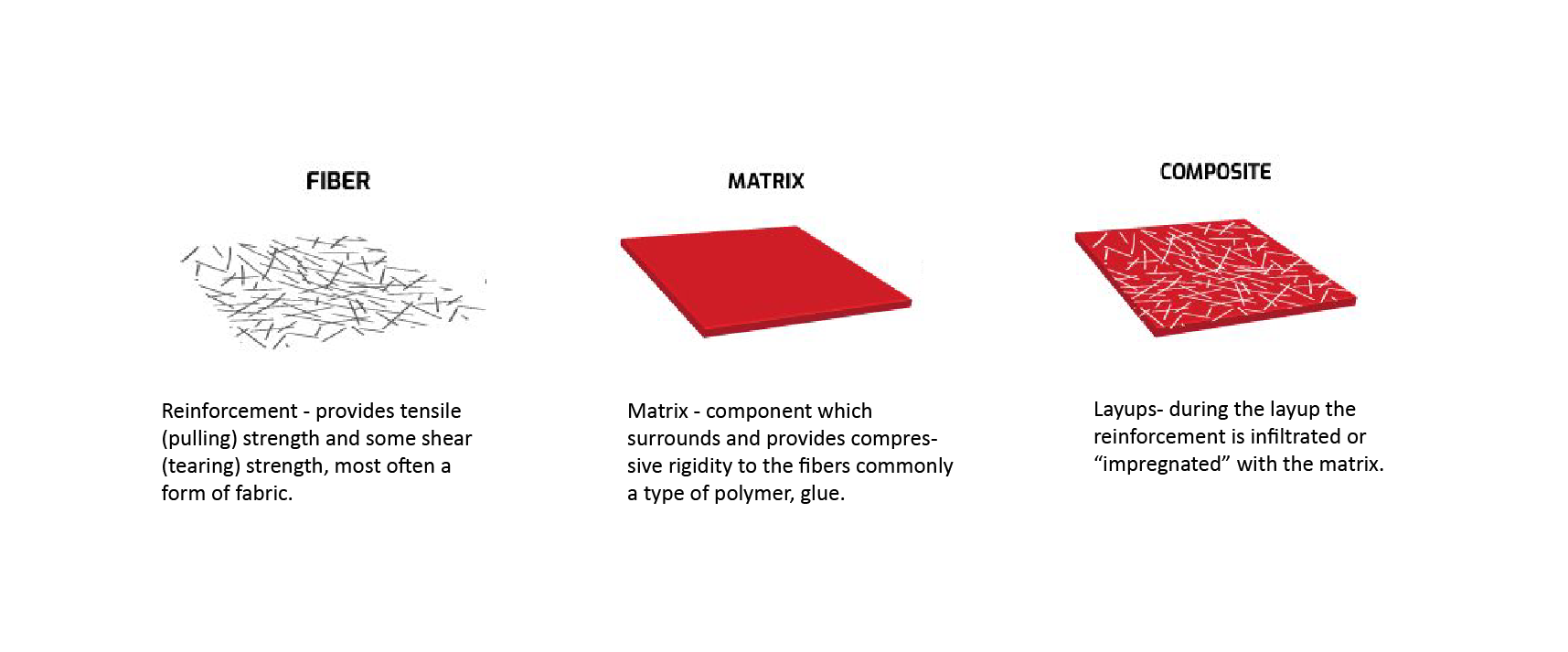

Composite material:

A composite material is any material made up of two or more dissimilar materials. In modern engineering, it typically refers to a reinforcement fiber embedded within a solidified matrix material.

Why use composites?

The most significant advantage of modern composite materials is that they are both lightweight and strong. By selecting an appropriate combination of matrix and reinforcement materials, it is possible to create a material that precisely meets the requirements of a specific application. Composites also offer design flexibility, as many can be molded into complex shapes.

![]()

Smart glass walls | Exterior panels:

Smart glass technology is an active glazing system that changes its state when electricity is applied. The unique particles or molecules within the film scatter or align as the film is switched on or off, allowing the glass to transition between opaque and transparent states.![]()

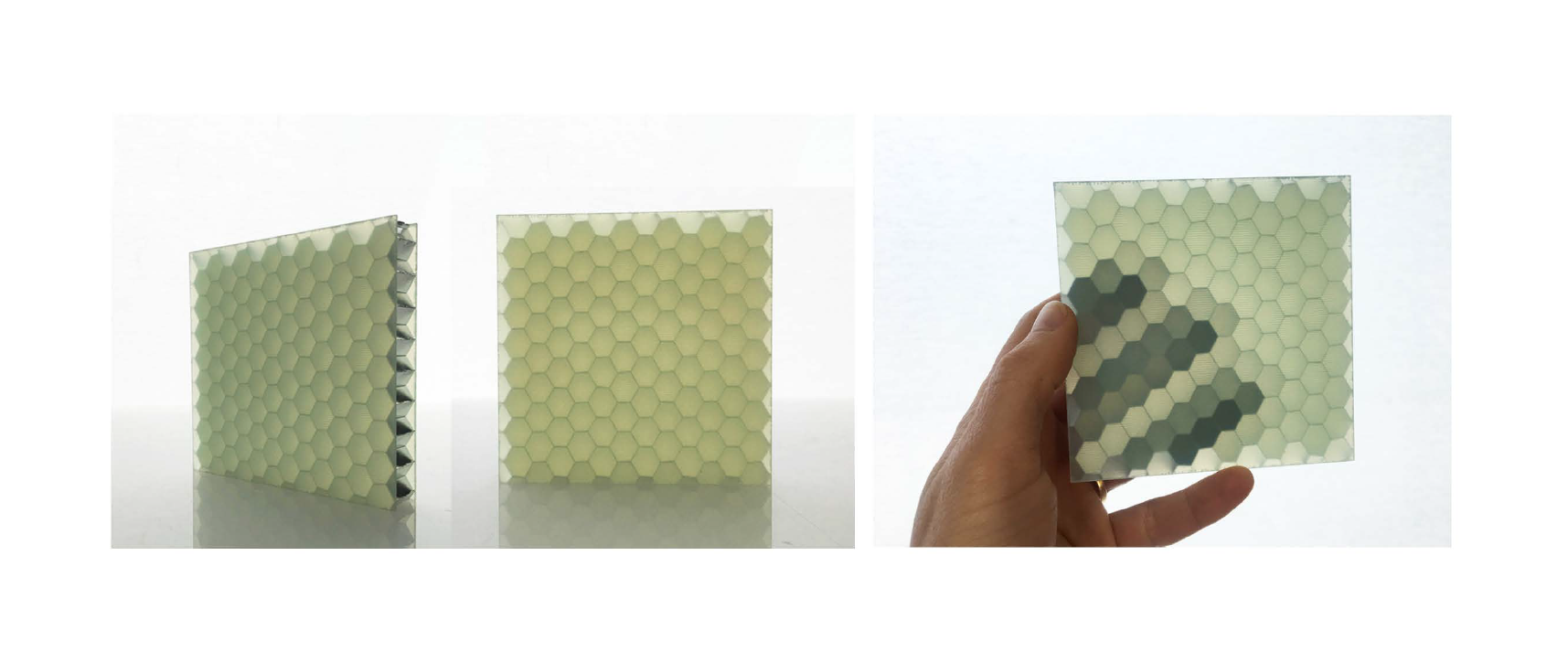

Pixel Panel | Fiberglass core | Interior panels :

PIXEL panels weigh only 30 lbs and are exceptionally stiff, making them very easy to handle and install while saving time, materials, and labor onsite. They can be cut with standard woodworking tools and finished with typical profiles and hardware, such as frames, handles, and hinges. These panels are ideally suited for applications such as partition panels, sliding doors, and backlit walls.

![]()

The most significant advantage of modern composite materials is that they are both lightweight and strong. By selecting an appropriate combination of matrix and reinforcement materials, it is possible to create a material that precisely meets the requirements of a specific application. Composites also offer design flexibility, as many can be molded into complex shapes.

Smart glass walls | Exterior panels:

Smart glass technology is an active glazing system that changes its state when electricity is applied. The unique particles or molecules within the film scatter or align as the film is switched on or off, allowing the glass to transition between opaque and transparent states.

Pixel Panel | Fiberglass core | Interior panels :

PIXEL panels weigh only 30 lbs and are exceptionally stiff, making them very easy to handle and install while saving time, materials, and labor onsite. They can be cut with standard woodworking tools and finished with typical profiles and hardware, such as frames, handles, and hinges. These panels are ideally suited for applications such as partition panels, sliding doors, and backlit walls.

The primary focus of the project is to develop a proposal for a micro-housing unit that can be scaled to small, medium, and large sizes, one that takes a strong conceptual approach to housing and reflects an innovative, creative, environmentally responsible, and culturally sensitive response to contemporary domesticity (based on the design guidelines from Here & Now, ACSA Competition). I began the concept design at the scale of a single unit, with the expectation that it could be proposed both as a single-family dwelling and as part of an aggregated grouping of units at a larger scale.

SITE 1 – 4 units on a lot in Desert Hot Springs, CA

SITE LOCATION:

Desert Hot Springs, CA. The site is located between San Jacinto St on the south, San Gorgonio on the north, Bubbling Wells Rd on the west, and Yerxa Rd on the East.

PROJECT SIZE:

Each lot is approximately 100’ x100’

SITE 2 – 60-unit Micro Housing development and park on a lot in Palm Springs, CA

SITE CONDITIONS:

On a currently undeveloped corner site in a suburban block of Palm Springs lies the vicinity of the Steel Development Houses, seven prefabricated steel residences designed by Donald Wexler (with Richard Harrison) and built by the Alexander Construction Co. between 1961 and 1962. These were part of a proposed tract of approximately 38 steel homes, sponsored by U.S. Steel, but rising steel costs halted the project after only seven were realized.

PROJECT SIZE:

Approx. 120,000 sf lot, 60 units